In the world of cement handling and bulk material logistics, the right unloading equipment can make a major difference in operational efficiency, safety, and long-term cost. One solution gaining momentum is the portable cement unloader, a mobile system used to transfer bulk cement from trucks, barges, or containers into silos or other storage units.

But does it justify the investment? This article examines the advantages, disadvantages, and key factors to consider when assessing portable cement unloaders for your operations.

What is a portable cement unloader and how does it work?

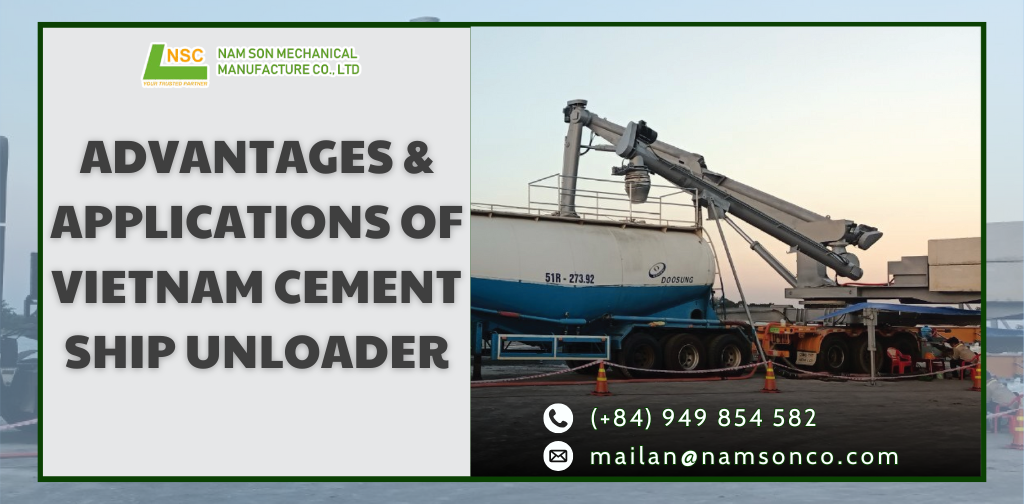

A cement unloader is a machine used to discharge cement either in bulk or in bags from transport vehicles such as cement trucks, containers, or barges, into silos or storage systems. Unlike stationary unloading systems, portable models offer mobility and flexibility across various job sites.

Most models use screw conveyors, vacuum pumps, or pneumatic conveying systems to move material. Advanced types function as automatic cement unloaders, requiring minimal manual input and often come with dust control features, making them environmentally compliant.

SEE MORE: What is a ship unloader?

Why should you consider investing in a portable cement unloader?

1. Flexibility across multiple job sites

One of the biggest advantages of a portable cement unloader is its unmatched flexibility. In modern construction environments, where projects often span remote locations, temporary worksites, or infrastructure upgrades along transport routes, the ability to relocate equipment easily becomes a key asset.

Portable unloaders are designed to move effortlessly between job sites, eliminating the need to install and dismantle fixed systems. Whether you’re operating in urban redevelopment zones or isolated rural projects, this flexibility reduces downtime and improves overall logistics. These units function as mobile cement unloading solutions, efficiently transferring material from cement tankers, bulk trucks, or even portside barges, making them ideal for decentralized construction operations.

In multi-phase projects or public infrastructure developments (like highways or wind farms), having a mobile cement unloader means you can maintain cement delivery and storage without the lag or cost of building permanent setups.

2. Reduced labor and faster operation

Labor efficiency is another compelling reason to invest in a portable cement unloader. Traditional cement unloading often demands multiple workers, especially when dealing with heavy hoses, manual clamps, or dust containment setups.

By contrast, modern bulk cement discharge systems come equipped with features such as:

− Automatic valve control

− Remote monitoring

−Self-cleaning filters

− Pneumatic conveying systems

These upgrades allow just one technician to manage the operation, reducing not only payroll expenses but also human error and injury risk.

Moreover, these unloaders boast fast cement unloading speeds capable of transferring tons of material in a fraction of the time required by manual systems. This directly impacts your project timelines and delivery schedules, enabling higher productivity and faster turnaround.

3. Environmental compliance and dust control

Environmental regulations surrounding cement handling have become increasingly strict in recent years. Excessive dust from traditional unloading systems contributes to air pollution and can endanger nearby communities as well as on-site personnel.

Portable cement unloaders are designed with advanced dust suppression features, including:

- Closed-loop conveying systems

- HEPA-grade vacuum filtration

- Sealed discharge ports

- Baghouse-style filters

These systems prevent cement powder emissions, ensuring compliance with environmental safety standards like OSHA and EPA (or local equivalents). In addition, better dust control improves working conditions and supports company sustainability initiatives.

For companies pursuing green construction certifications or ISO environmental standards, investing in a portable unloader can significantly enhance their compliance profile and brand reputation.

4. No need for fixed infrastructure

Traditional unloading systems typically involve fixed silos, conveyor lines, foundation structures, and building permits all of which add substantial upfront and maintenance costs. With a portable cement unloader, these are largely unnecessary.

You get an all-in-one cement discharge solution that can be deployed rapidly without lengthy setup procedures. This is especially valuable for:

- Short-term contracts

- Emergency repair works

- Pop-up concrete batching plants

- Mobile job site silos

The system can be positioned on flat ground, connected to a bulk cement container, and begin unloading within hours, not days. There’s no need to wait on permits, structural assessments, or long installation timelines.

This not only lowers capital expenditure (CapEx) but also allows companies to scale operations faster.

5. Long-term cost efficiency

At first glance, the initial investment for a portable cement unloader might seem higher than basic manual methods. However, the total cost of ownership (TCO) is significantly lower over time due to:

- Fewer breakdowns

- Lower maintenance costs

- Reduced labor dependency

- Optimized fuel and energy consumption

- Shorter loading/unloading cycles

Companies using portable cement unloaders alongside mobile cement transfer stations, bulk bag dischargers, or pneumatic silo feeding systems often report up to 30% savings in operational budgets within the first two years of use.

Additionally, these systems have modular upgrades, meaning you can extend their utility over multiple projects without replacing the core unit. When considered from a long-term asset value perspective, the return on investment (ROI) can be quite substantial.

Some models even include data logging and real-time diagnostics, helping operators identify inefficiencies and reduce waste, which further improves profitability.

When is a portable cement unloader not the right choice?

1. Fixed plants with high-volume needs

If your operations are based in a single fixed location, with high and stable cement throughput, then a stationary cement unloading system may be more cost-effective and powerful in the long run.

2. Budget constraints

High-tech portable unloaders especially those with dust control or automation may exceed the budget of smaller contractors. Simpler mechanical unloaders or shared infrastructure might be more feasible.

3. Ultra-high unloading capacity required

For facilities needing to unload massive quantities of cement, such as cement factories or bulk ship terminals, portable units may fall short. Instead, ship cement unloaders or large pneumatic systems are more suitable.

SEE MORE: Choosing the right cement ship unloading system in Vietnam

Conclusion: Should you invest in a portable cement unloader?

The answer depends on your project needs. If you’re managing mobile construction sites, require on-demand flexibility, or want to cut down on labor and setup costs, a portable cement unloader is a smart investment.

However, if you’re working from a centralized site with high and regular throughput, a fixed unloading system may be a better fit.

Need help choosing the right cement unloader?

Contact our experts now for tailored solutions to boost your unloading efficiency.

CONTACT US

- Website: namsonco.com | mayhuthoi.com

- Alibaba: dthson.trustpass.alibaba.com

- Facebook: facebook.com/NamSonPneumaticConveyor

- Zalo/Whatsapp: (+84) 949854582

- Email: mailan@namsonco.com | thanhson@namsonco.com