Cement is the backbone of every construction project, but improper storage can lead to costly problems. A cement silo offers the most reliable and durable solution for storing bulk cement and other construction materials. From preventing moisture damage to improving efficiency, silos have become an indispensable asset for modern building sites.

Introduction to cement silo

In the construction industry, quality, safety, and efficiency depend heavily on how raw materials are stored and managed. Cement, as the backbone of concrete and mortar, requires careful handling. Even slight exposure to moisture can cause clumping, reduce binding strength, and ultimately compromise the durability of a structure. For this reason, traditional storage methods such as cement bags or open containers are no longer sufficient for large-scale or long-term projects.

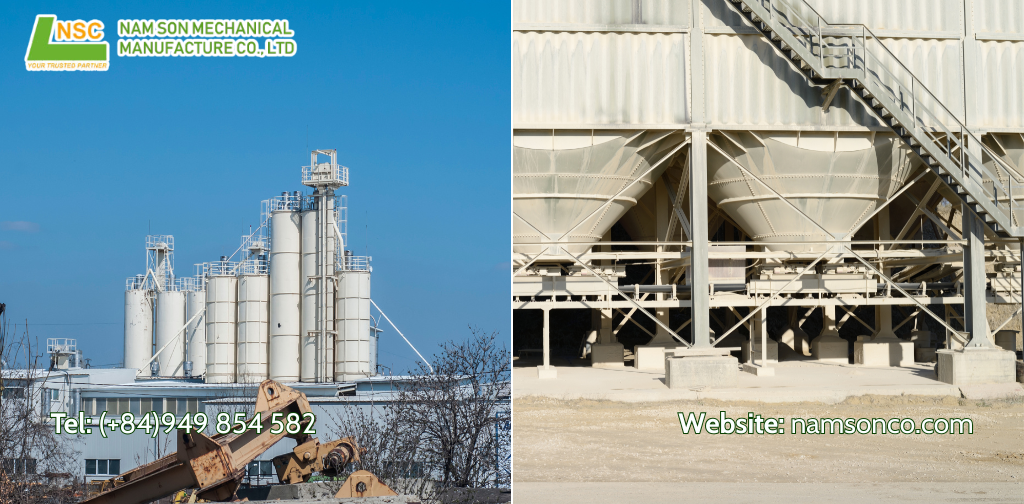

This is where the cement silo, also referred to as a cement storage silo, bulk cement silo, or concrete silo, becomes indispensable. A silo is not just a container; it is a purpose-built system engineered to provide reliable and durable storage for construction materials. By offering a controlled environment, it ensures that cement remains dry, uncontaminated, and readily available when needed.

From small construction sites to massive infrastructure projects, the construction silo has become a cornerstone of modern building logistics. It supports continuous cement supply, minimizes losses, and enhances overall project performance.

SEE MORE: What is cement silo storage and why it matters in construction

Structure and types of cement silo

1. Basic structure of a cement silo

A typical cement silo is designed with durability and safety in mind. Most are made from high-strength steel (steel cement silo, galvanized cement silo) or reinforced concrete. The essential components include:

- Silo top – equipped with a cement silo filter and silo dust collector to prevent environmental pollution.

- Silo body – cylindrical or horizontal, built to withstand pressure, wind loads, and corrosion.

- Cone section – at the base, the cement silo cone allows smooth discharge via a cement silo discharge system.

- Safety features – such as a cement silo valve, level indicator, and aeration system ensure uninterrupted cement flow and safe operation.

These features transform the silo into a robust cement storage system capable of handling large volumes of material securely.

2. Types of cement silo

Cement silos are manufactured in several variations to suit different project requirements:

a. By orientation:

- Vertical cement silo: compact, space-saving, and ideal for high-capacity storage.

- Horizontal cement silo: easier to install and relocate, suitable for temporary sites.

b. By mobility:

- Stationary cement silo: designed for permanent facilities such as concrete plants.

- Portable cement silo or mobile cement silo: flexible and easy to transport between sites.

c. By assembly method:

- Bolted cement silo: modular design, convenient for shipping and on-site assembly.

- Welded cement silo: highly durable and suitable for long-term, heavy-duty use.

d. By capacity:

- 50-ton cement silo, 100-ton cement silo, 200-ton cement silo for mid-size projects.

- Mini cement silo for smaller construction needs.

- Large cement silo or industrial-size cement silo for mega infrastructure developments.

This wide variety ensures that every contractor can find a silo solution tailored to their scale and environment.

How a cement silo ensures reliable storage

The working principle of a cement silo highlights why it is so dependable. Bulk cement is delivered by tanker trucks and transferred into the silo through a silo loading system. Once inside, the cement is sealed from external conditions.

When required, the cement flows downward to the cement silo discharge system. Aided by an aeration system, the cement moves smoothly without clumping. The cement silo valve controls flow, while the level indicator provides real-time monitoring of storage capacity.

This controlled cycle ensures:

- Protection from moisture – the silo creates a sealed environment that keeps cement dry.

- Operational reliability – predictable and smooth discharge avoids production delays.

- Minimal wastage – unlike bags that can tear or spoil, bulk silos preserve every ton of cement.

In this way, the cement silo stands as a reliable cement storage solution, vital for maintaining quality throughout a project.

SEE MORE: Top 5 benefits of using a modern cement silo system

Applications and advantages of cement silo

1. Key applications in construction

The role of cement silos extends far beyond simple storage. They are critical to multiple industries:

- Concrete production – silos provide a consistent supply to the concrete batching plant, silos and the precast concrete industry.

- Dry mortar and plaster – storing powdered materials for ready-mix mortar.

- Building materials industry – handling cement, lime, fly ash, and gypsum.

- Logistics and transport – with cement transport containers, silo truck loading, and bulk handling systems, silos streamline supply chains.

Wherever powdered materials must be kept safe and dry, the cement silo provides unmatched reliability.

2. Advantages of a cement silo for reliable and durable storage

The adoption of silos is not just a matter of convenience; it delivers tangible benefits:

- Durability and long service life: Durable cement silos and long-lasting cement silos are engineered to withstand corrosion, weather, and heavy use.

- Cost-effectiveness: By reducing losses and labor, a cost-effective cement silo helps contractors save money.

- Safety and compliance: Safe cement storage systems reduce dust hazards and align with environmental standards.

- Eco-friendliness: Eco-friendly cement silos equipped with dust collectors minimize emissions and maintain cleaner job sites.

- Space optimization: From space-saving silos to high-capacity silos, they make efficient use of land while providing massive storage.

- Ease of use: Easy-installation silos and low-maintenance silos allow quick setup and reliable operation.

These benefits explain why cement silos are considered essential to durable storage of construction materials.

Conclusion: Cement silo as the foundation of reliable storage

As construction projects grow in scale and complexity, the importance of material reliability becomes greater than ever. Cement, being central to almost every structure, must be stored under conditions that guarantee strength and consistency. The cement silo provides reliable and durable storage for construction materials, ensuring that cement is always available, uncontaminated, and ready for use.

Whether it is a bulk cement silo serving a massive infrastructure project or a portable cement silo supporting a temporary site, the promise remains the same: secure, efficient, and dependable cement storage.

By protecting raw materials, reducing costs, and enhancing sustainability, cement silos are not just a storage option—they are a foundation for modern construction excellence.

Looking for a high-quality cement silo for your next project? Contact our team today for expert advice, customized solutions, and reliable equipment that ensures your construction materials stay safe and durable.

Contact us

Website: namsonco.com | mayhuthoi.com

Alibaba: dthson.trustpass.alibaba.com

Zalo/Whatsapp: (+84) 949854582

Email: mailan@namsonco.com | thanhson@namsonco.com